Customization

Professional Excellence in Service

Relentless Improvement, Pioneering Industry Standards

Independent Innovation

Leverages patented technologies and simulation systems (e.g., DFM/DFA) to develop high-performance proprietary structures, breaking traditional performance limitations and ensuring technological leadership.

Tailored Customization

Collaborates end-to-end from requirement analysis to implementation, enabling parametric rapid modifications (shaft distance/torque/ material) for agile adaptation to non-standard needs and precise application matching.

OEM/ODM Service

Provides full OEM/ODM solutions with seamless compliance to client standards (ISO/industry norms), delivering turnkey production from drawings to mass manufacturing while ensuring batch consistency and supply chain synergy.

Customized process

End-to-End Precision Transmission Custom Solutions

Step 1:

Consultation and Communication

Mutual Understanding Through Communication: Alignment of Needs and Services.

Step 2:

Requirements Confirmation

Formalize Client Requirements and Specifications to Generate Standardized Technical Design Documentation.

Step 3:

Execute a Contract

Finalize Collaborative Parameters: Objectives, Timeline, Costs, Expenses, and Deliverables.

Step 4:

Development and Design

Implement Client Specifications with Real-Time Telemetry; Execute Design & Prototype Qualification including Modifications and Validation.

Step 5:

Product Handover

Execute Formal Handover of Complete Design Documentation, Product Units, and Certified Inspection Reports.

Step 6:

Post-Handover Sustaining Services

Post-Handover Issue Resolution Protocols with Corrective and Preventive Action (CAPA) Implementation.

Our Customization Capability

Your Transmission Vision, Our Custom Expertise

Scheme Discussion

Design and Development

Design Verification

Agile Development

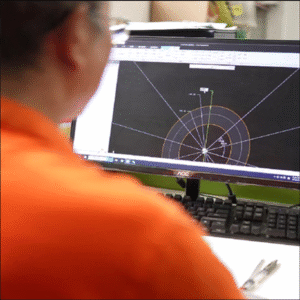

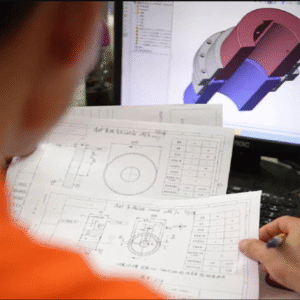

Deeply understands requirements, rapidly responds to design changes. Utilizes advanced CAD/CAE tools and extensive experience databases to deliver precise custom transmission solutions with matched performance.

Flexible Smart Manufacturing

Leverages flexible production lines and precision equipment (CNC, gear grinding, etc.) to adapt processes, enabling efficient and stable production of high-precision custom parts in small batches with high variety.

factory

factory

factory

Equipment Testing

Production equipment 1

Production equipment 2

Production equipment 3

Production equipment 4

End-to-End Control

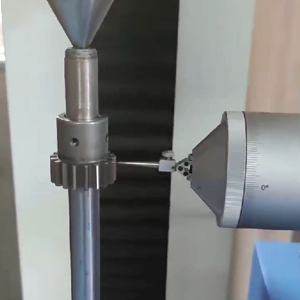

Implements rigorous inspection throughout the entire process from raw materials to finished goods. Employs precision instruments and specialized testing to ensure every custom transmission part meets dedicated standards, with full traceability.

Customize Now

Get a Free Custom Quote Today

21 years of industry R&D and production experience

We are here to provide support and protection for you, and sincerely look forward to your contact

AODISI